Innovation

Pioneering new solutions for some of the industry’s biggest challenges

We are collaborating with multiple operators around the world to deliver new solutions for some of the industry’s biggest challenges.

We're not afraid of tackling the big questions to help shape our future.

We know that advancement means change, innovation and doing things differently and we know that our problem-solving skills and fresh approach will deliver the very best solutions.

Together our team is building an outstanding number of patents and developing a valuable portfolio of intellectual property, placing us at the forefront of energy innovation. Innovating new technology, pushing the boundaries of capability and adding value to the industry are some of our driving principles.

Some of our innovative technologies are showcased below.

Unique technology solutions for cross-sector applications

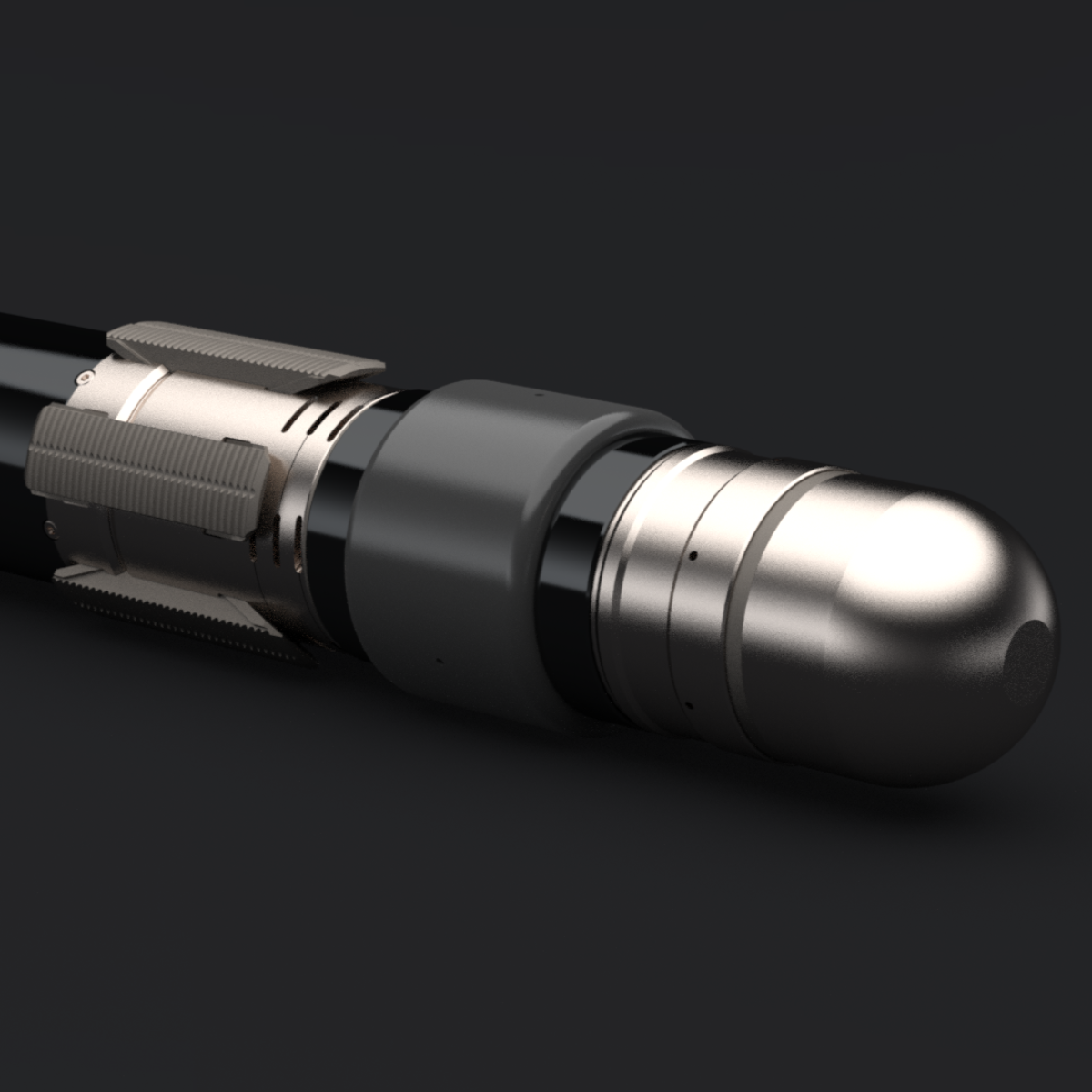

Plugs and Straddles

FUNCTIONALITY

DEPLOYMENT

SECTORS

DTI have designed and manufactured bridge plugs since 2017. We have three key ranges - PKB, UHX and IX.

The PKB bridge plug meets a need for a low-cost, easy to run plug in 2-⅜” to 4-½” completions with a 5,000 psi maximum working pressure. It is designed to be run and set on slickline without any special setting tools and run and pulled using standard GS pulling tools. Typically, DTI has supplied this bridge plug with melon or prong type equalizing devices however it is adaptable and can be used as a gauge hanger, standing valve or injection valve. The PKB bridge plug has also been adapted to be used as a packoff as part of a straddle sleeve and for gas lift systems. We have an excellent track record and have supplied >150 PKB plugs and packers.

We introduced our Ultra High Expansion (UHX) M-Bubble Plug and Ultra High Expansion (UHX) Packoff in 2021. These were the result of four years of research and development on an additive manufactured metal element (M-Bubble) which enables us to produce a plug with an unrivalled combination of expansion, pressure and temperature ratings. The design of the UHX plugs and packers helps to solve a range of complex plugging, sealing and isolation challenges in a variety of wells and are typically used in applications where the tool is required to pass through the completion string and set and seal in a lower casing or liner. Most applications to date have been for water shut off, however the products are also suitable for zonal isolation, plug and abandonment and CCUS applications. The standard sizes of the UHX M-Bubble are 2-⅛” OD tools that will set and seal in up to 6-⅝” casing/ liner and 2-⅝” OD tools that will set and seal in up to 7” casing/ liner. Multiple other sizes, temperatures and pressure variants are in development.

More recently, and in response to customer demand, we have introduced a range of Inter-Expansion (IX) sealing solutions. The IX range fills a gap between the PKB sealing solution and the UHX sealing solution. The IX bridge plugs and packoffs are rated to 7500 psi working pressure and are API 11D V3 rated. With straddle sleeves in mind they have been designed with an excellent working ID to pressure rating ratio. The IX plugs can be run and set on slickline/ e-line using a powered setting tool or on coiled tubing using a hydraulic setting tool. The current range for IX plugs and packers is from 2-⅜” tubing through to 7” tubing.

PermaSeal

FUNCTIONALITY

DEPLOYMENT

SECTORS

PermaSeal features a patented metal sealing connector and tool joint technology to deliver a high-performance solution for extreme well applications. The technology is designed to replace elastomer seals and withstand pressures in excess of 20,000 psi and temperatures of 200 degrees C and beyond with enhanced integrity.

PermaSeal is designed for the most aggressive well applications including high temperature or high-pressure intervention operations or permanent well installations such as velocity strings. When our PermaSeal connectors are combined with our Twin Flapper Check Valve for well intervention, a safe and reliable gas-tight well barrier is created.

PermaSeal is suitable for applications across a range of energy sectors. Its CRA metal seal ring ensures compatibility with even the most aggressive well fluids and the most extreme of well conditions, even up to 30,000 psi.

Annular Safety Valve

FUNCTIONALITY

DEPLOYMENT

SECTORS

DTI’s Annular Safety Valve (ASV)can be used in hydrogen and natural gas storage wells plus traditional gas lift and gas producer wells. It has been developed from our patented Slim Pump Safety Valve and offers a range of valuable features and benefits. The ASV provides leak-tight sealing and the ability to open and close in both directions at full working pressure (to 5,000 psi), allowing for both injection and production. A large flow area also supports high volume operations.

The ASV incorporates a control line pass-thru and is deployed into the nipple profile of a Tubing Retrievable Surface Controlled Sub Surface Safety Valve (TRSCSSSV) to enable separate hydraulic control of both valves from surface. It is surface testable and allows quick reinstatement of a safety valve in the event of failure. The ASV has been deployed in a pilot hydrogen project in France to demonstrate the viability of salt caverns for large-scale green hydrogen storage.

Extreme Temperature Safety Valve

FUNCTIONALITY

DEPLOYMENT

SECTORS

DTI has developed proprietary technology for an all-metal downhole safety valve to withstand extreme temperature applications of between -90C and +340 degrees C. This exceeds the level that most HPHT safety valves can currently achieve (-30 - 245 C) and makes it suitable for a range of cross sector applications including oil and gas, geothermal and CCUS.

Twin Flapper Check Valve Cartridge

FUNCTIONALITY

DEPLOYMENT

SECTORS

DTI pioneered the design of the single-piece Twin Flapper Check Valve Cartridge to reduce critical leak path, assembly and redress requirements and provide the ultimate in sealing reliability. The single-piece cartridge is key to our Twin Flapper Check Valve and range of Motorhead Assemblies.

Combined with our PermaSeal technology, this valve can provide the ultimate barrier for a range of energy sector applications. The hybrid elastomer/ metal to metal flapper seal and the Permaseal CRA metal seal ring ensures compatibility with even the most aggressive well fluids and the most extreme of well conditions, even up to 30,000 psi.

Research &

Development

Our design, engineering, manufacturing and certification services are supported by an extensive range of on-site R&D facilities which include pressure test bays, flow testing and temperature testing.

We are experts in additive manufacturing, producing new designs to outperform conventional expectations and ultimately help our clients to achieve more.

Visit our Capabilities page to find out more and discover our track record for individually engineered project solutions.

With over 10,000 products designed for every type of well, and a team of in-house design and engineering talent, we can deliver the solutions you need.

We're committed to your success and will support you through tool supply, advice, training and first deployment so get in touch today to discover more.

To keep up to date with our latest activity please follow us on LinkedIn and check out our news and media page for handy downloads.