Products

DTI supply over 10,000 downhole tools to clients across different energy sectors around the world. Below are a selection of some of our most popular solutions. Use the search and filter functions to find out more about each, but if you can't find what you're looking for please contact us, as not every solution is listed.

Filter By

Functionality

Deployment Type

Sectors

Featured Product Lines

Product Types

It looks like there are no products matching your search parameters.

Get in touch and we'll help you find the right product.

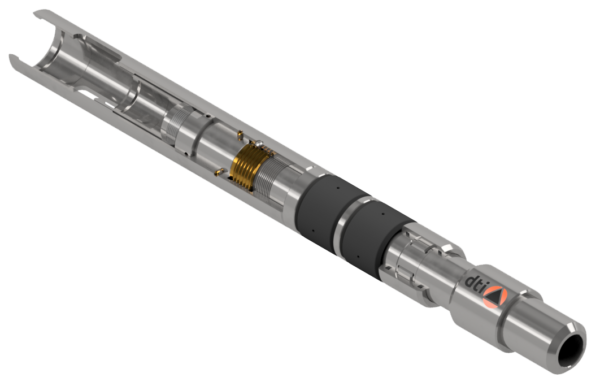

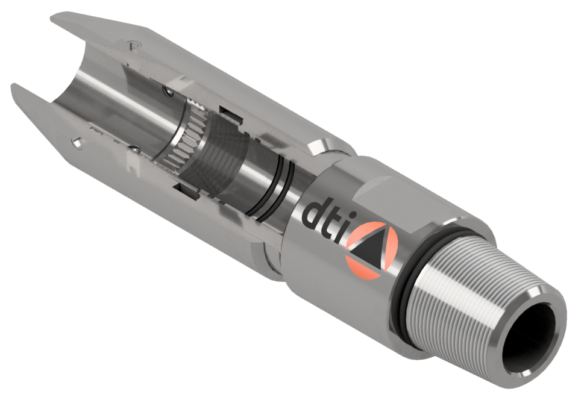

Ultra-High Expansion (UHX) M-Bubble Plug

The UHX Plug offers industry-leading expansion and high-pressure, in-flow deployment capability, helping to solve a range of complex plugging, sealing and isolation challenges in a variety of wells.

Ultra High Expansion (UHX) Packoff

With industry-leading expansion and high-pressure, in-flow deployment capability, our UHX solutions help to solve a range of complex plugging, sealing and isolation challenges in a variety of wells.

IX Intermediate Expansion Bridge Plug

DTI’s Inter-Expansion (IX) technology offers retrievable or permanent plugging with in-flow, thru-tubing deployment. They provide an API-11D V3 rated barrier up to 7,500psi.

PKB Bridge Plug

DTI's PKB bridge plug meets the need for a low-cost, easy to run plug in 2-3/8” to 4-1/2” completions with a 5,000 psi maximum working pressure.

PKO Tubing Packoff

DTI's PKO Tubing Packoff is used to seal inside production or injection tubing. The large internal diameter makes this tool suitable for applications such as tubing patches, straddle sleeves and hanging flow control valves.

Annular Safety Valve (Gas Storage)

The gas storage Annular Safety Valve (ASV) is designed for conventional gas and hydrogen storage wells.

Extreme Temperature Safety Valve

Our Extreme Temperature Safety Valve (ETSV) is designed for a wide range of extreme conditions in carbon capture, steam flood and geothermal applications. The ETSV is the highest temperature rated safety valve on the market. It is fully metallic, using our proprietary dynamic metal-to-metal seal for rod piston control.

Slim Pump Safety Valve

DTI's unique Slim Pump Safety Valve is incorporated into cable deployed ESP or jet pump systems, providing an API qualified valve with minimal additional system complexity. It is set at the pump depth and activated by pump switch on and off. No control lines, surface control or cable sealing operations are required.

Extreme Duty Motorhead

DTI's Extreme Duty Motorhead Assembly is a compact bottom hole assembly incorporating a Twin Flapper Check Valve, Release Joint and Circulation Sub. It is designed for operations where high shock loads, vibrations, tensile and/ or torque forces are expected. It is robust, reliable, easy to redress and rated to 10,000PSI.

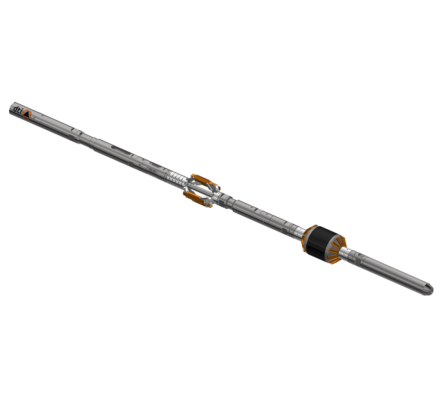

Twin Flapper Check Valve

DTI's Twin Flapper Check Valve provides a dual barrier within the coiled tubing tool string as safety critical protection against fluid back flow.

Twin Flapper Check Valve Ultra

The DTI Twin Flapper Check Valve provides a dual barrier within the coiled tubing tool string as safety critical protection against fluid back flow.

Twin Flapper Check Valve with Lock Out Sleeve

The DTI twin flapper check valve acts as a dual barrier within the tool string against fluid back flow through the coiled tubing. The lockout sleeve enables the reverse circulation of fluid from the well through the coiled tubing.

Injection Valve

DTI's Injection Valve is run below a Lock Mandrel or DTI Bridge Plug to provide a secure well barrier in the event that pressure integrity above the Injection Valve is compromised.

Three Way Circulation Valve

DTI's Three Way Circulation Valve is specifically designed for bypassing CT manipulation tools during high rate circulation.

Milling Circulation Valve

DTI's Milling Circulation Valve provides a constant fluid flow path to the motor or BHA during milling operations while providing a means of high volume circulation to the annulus when required.

PermaSeal Torque Through External Slip Connector

The DTI patented PermaSeal Torque Through Slip Connector features DTI's high performance metal-to-metal seal for extreme well applications. Designed to withstand high pressure up to 10,000 psi and temperatures the Permaseal Torque Through Slip Connector is designed to be used for permanent well installations as well as high pressure intervention operations.

PermaSeal Torque Through External Slip Connector Ultra

The DTI patented PermaSeal Torque Through Slip Connector features DTI's high performance metal-to-metal seal for extreme well applications. Designed to withstand high pressure up to 15000 psi and temperatures the Permaseal Torque Through Slip Connector is designed to be used for permanent well installations as well as high pressure intervention operations.

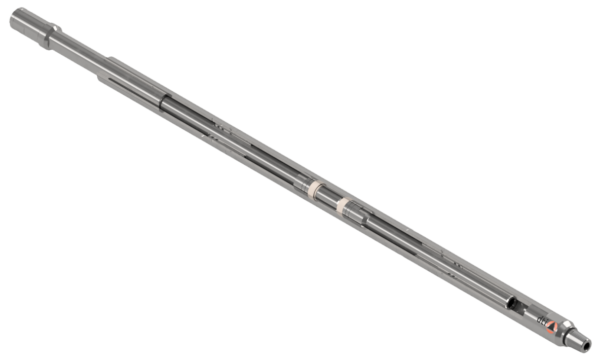

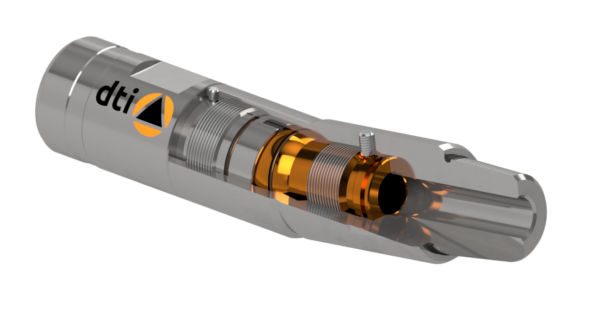

Ultra Duty Motorhead

DTI's Ultra Duty Motorhead Assembly is a compact bottom hole assembly incorporating a Twin Flapper Check Valve, Release Joint and Circulation Sub. It is designed for operations where high shock loads, vibrations, tensile and/ or torque forces are expected. It is robust, reliable, easy to redress and rated to 15,000PSI.

Flow Activated Shifting Tool - Single Acting

The DTI Coiled Tubing Single Acting Shifting Tool is a normally retracted hydraulic action tool used to position the closing sleeve of most Sliding Side Doors to the open position or to the closed position.

Flow Activated Shifting Tool - Dual Acting

The DTI Coiled Tubing Dual Acting Shifting Tool is a normally retracted hydraulic action tool used to position the closing sleeve of most Sliding Side Doors to the open position or to the closed position.

Flow Activated GS Pulling Tool

The Coiled Tubing DTI GS Pulling Tool is a hydraulic release action tool used for running or retrieving downhole tools with standard size internal fishing necks.

Flow Activated External Heavy Duty Pulling Tool

The Flow Activated Heavy Duty Pulling Tool is a hydraulic release action tool used for running or retrieving downhole tools with standard size external fishing necks.

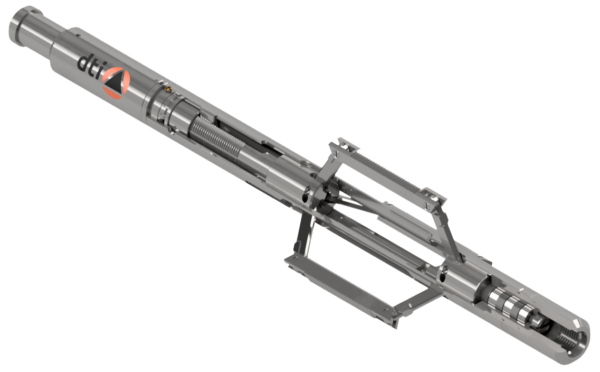

Expanding Flow Activated Bow Spring Centraliser

The Expanding Bow Spring Centraliser is a hydraulic tool with normally retracted bow springs. When fluid flow/ pressure at the tool is increased, the bow springs will expand to the tubing I.D. and centralise the tool string.

Electric Line Heavy Duty Bowspring Centraliser

DTI’s E-Series Heavy Duty Bowspring Centraliser (E-HDBC) is designed for heavy duty activities such as perforating and tubing punches/cuts. E-HDBCs can be supplied with a range of bow spring sets to suit different applications and are easy to replace or change.

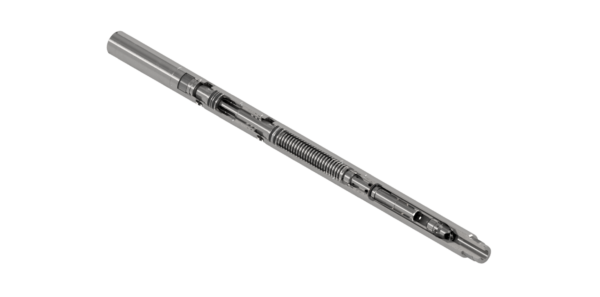

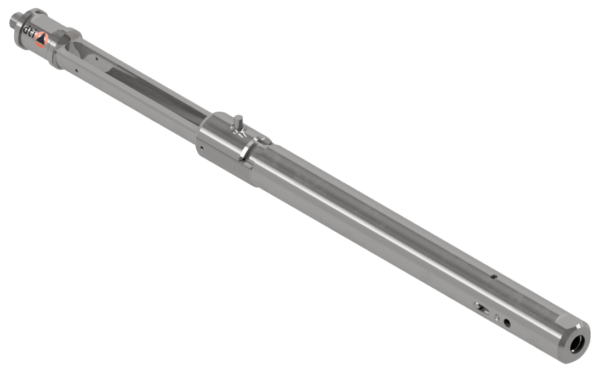

Dual Action CT Hydraulic Jar

DTI Dual Action Hydraulic Jars enables repeatable upward or downward jarring blows to the work string. DTI have refined the design of our jars over many years of successful deployments and now feature DTI proprietary Vortex Metering Technology (VMT) for extremely reliable operation.

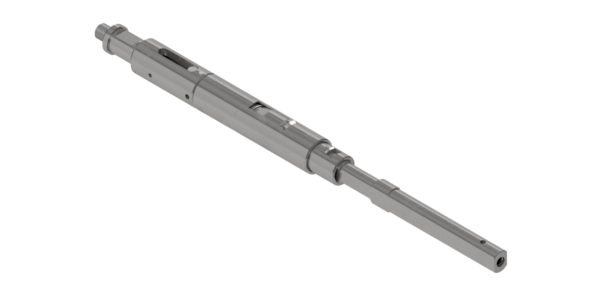

Dual Action CT Spring Jar

The DTI Dual Action CT Spring Jar enables repeatable upward or downward jarring blows to the work string.

Dual Action CT Spring Accelerator

DTI's Coiled Tubing Dual Action Spring Accelerator is used with a DTI Dual Action Mechanical or Hydraulic Jar. The Accelerator provides stored tension or compression energy in addition to the coiled tubing spring effect.

Dual Action CT Hydraulic Accelerator

The DTI CT Hydraulic Accelerator is used with the DTI Dual Action Hydraulic Jar. The Accelerator provides stored tension or compression energy in addition to the coiled tubing spring effect.

Hammerhead Up Impact Hammer

The DTI Hammerhead Upstroke Impact Hammer delivers a controllable high frequency up impact to a downhole device.

Hammerhead Down Impact Hammer

The DTI Hammerhead Downstroke Impact Hammer delivers a controllable high frequency down impact to a downhole device.

Hammerhead Accelerator

The DTI Dual Acting Hammer Head Accelerator intensifies the up or down jarring force of the Hammer Head flow hammer tools.

Surface Test PermaSeal External Slip Connector

The DTI 'Permaseal' External Slip Connector provides a quick and simple means of connecting the coiled tubing string to surface equipment so that pressure testing can be carried out.

High Expansion Gauge Hanger

The Expanding Gauge/ Instrument Hanger can be used to hang a subsurface device in a location with no landing nipple. Run on a suitable explosive or electric setting tool, the Instrument Hanger can pass through smaller inside diameter tubing and then set in larger inside diameter tubing or casing.

High Expansion Gauge Hanger Running Tool

DTI's High Expansion Gauge Hanger Running Tool is a wireline tool specifically designed to run and set the DTI High Expansion Instrument Hanger into the well bore.

Hydraulic Knuckle Joint

DTI's Hydraulic Knuckle Joint enables a controlled deviation of up to 15° to be applied to the bottom hole assembly for multi-lateral entry or for cleaning or jetting tunneling applications.

External Dimple Connector

The DTI External Dimple Connector forms a full bore sealed joint between the outside of the coiled tubing and the coiled tubing tool string. A pattern of set screws in the body of the connector are locked into pre-formed dimples made on the outside of the coiled tubing using a DTI Dimple tool.

Internal Dimple Connector

The DTI Internal Dimple Connector forms a sealed joint between the coiled tubing and the CT tool string. The Connector outside diameter can match the coiled tubing or the tool string outside diameter.

External Slip Dimple Connector

The DTI External Slip Dimple Connector combines the strength of the Slip and Dimple connectors to form a very strong connector capable of transmitting high tensile loads and torque.

External Slip Connector

The DTI External Slip Connector forms a full bore sealed joint between the outside of the coiled tubing and the tool string. The tool is made up by pushing the slips over the outside of the coiled tubing and then making up the top sub. No special tools are required.

External Torque Through Slip Connector

The DTI External Torque Thru Slip Connector is a very high strength connector which is easy to make up and is also suitable for demanding milling operations.

Self-Aligning Connector

The DTI Self Aligning Connector is a tool that enables the connection and disconnection of the CT tool string at surface where rotation of the toolstring is restricted preventing the make up of conventional threaded connections.

Roll-On Connector

The DTI Roll On Connector forms a sealed joint between the inside of the coiled tubing and the CT tool string or another line of coiled tubing. The joint O.D. is the same as the coiled tubing.

Extreme Duty Drop Ball Release Joint

The Extreme Duty Drop Ball Release Joint enables the controlled and safe release of the tool string from the coiled tubing should the tool string get stuck.

High Torque Indexing Tool

The DTI High Torque Indexing Tool can be used in any application where a high torque rotation of the BHA is required. Hydraulic toolstring pressure is converted to torque of up to 600FT-LBS and a pre-determined rotation of 15-45°. Each time the toolstring pressure is bled off and increased the High Torque Indexing Tool cycles again, resulting in another tool-string rotation.

Ultra Duty Drop Ball Release Joint

The DTI Ultra Duty Drop Ball Release Joint enables the controlled and safe release of the tool string from the coiled tubing should the tool string get stuck.

Tubing Perforator

The DTI Tubing Perforator is a mechanically operated punch assembly which is designed to make a single perforation in the production tubing wall per wireline run.

R-Line & X-Line Running Tool

DTI's X & R Line Running Tool is used to run and set locking mandrels into their matching landing nipples.

R Lock Mandrel

The DTIR Lock Mandrel is sized by the internal seal bore of the corresponding selective R landing nipple that it locates and locks into.

RN Lock Mandrel

DTIRN Lock Mandrels enable the positive landing and locking of subsurface flow control equipment into their matching tubing ‘no go’ nipple profiles.

X Lock Mandrel

DTIX Lock Mandrels enable the positive landing and locking of subsurface flow control equipment into their matching tubing 'selective' nipple profiles.

XN Lock Mandrel

The DTIXN Lock Mandrel is sized by the internal seal bore of the corresponding bottom no-go XN landing nipple that it locates and locks into.

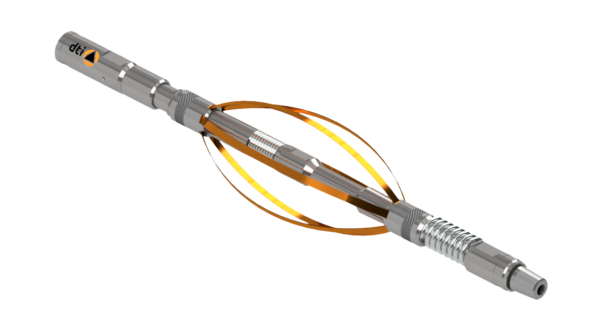

E-Swivel

DTI’s unique E-Swivel Joint can be added to the tool string to mitigate against twist in the wire, allowing full 360 degree rotation.

E-Knuckle

The E-Knuckle joint can be added to the tool string to allow passage through dog-legs or collapsed sections of tubing more easily.

E-Shock

DTI E-Shock can be added to the tool string to dampen impact shock and prevent damage to sensitive instrumentation, while sustaining the string weight.

E-Cablehead

DTI’s Interlock Cablehead provides a mechanical and electrical connection between the wireline (mono conductor) and the tool string. Its unique design incorporates an interlock protected weak point that allows the cable to be pulled free should the tool string become stuck in the wellbore.

E-Centraliser

The E-Line Centraliser is a combined adjustable bow spring or roller centraliser that delivers reduced complexity, enhanced reliability and reduced maintenance.

E-De-Centraliser

E-Weight Bars can be added to the tool string to increase their mass. They can be supplied as solid bars or with lead or tungsten billets.

E-Weight Bar

DTI’s E-Weight Bars can be added to the tool string to increase the mass of tool strings. The E-Weight Bars can be supplied as solid or with lead or tungsten fillers to increase their mass.

PermaSeal CT Barrier

The DTI PermaSeal CT Barrier combines uses DTI's patented PermaSeal technology , combining the DTI PermaSeal Coiled Tubing Connector with a PermaSeal Twin Flapper Check Valve to provide the ultimate integral metal-to-metal well barrier.

Drop Ball Circulation Valve

The DTI Circulation Valve allows the circulation of fluid through the CT tool under normal operating conditions. By dropping a ball, this circulation path is closed off and fluid is diverted from the CT tool string to the well via flow ports.

Rupture Plug Circulation Valve

The Circulation Valve Rupture Plug allows the circulation of fluid through the CT tool under normal operating conditions. By increasing CT pressure to a predetermined value, the rupture plug will blow out, thereby opening a flow path from the tool string to the well.

Dual Drop Ball / Rupture Plug Circulation Valve

The DTI CV Dual Action combines the drop ball and rupture plug circulation features into one tool. It allows the circulation of fluid through the CT tool under normal operating conditions.

Drop Ball Circulation Valve (Normally Open)

The Normally Open Drop Ball Circulation Valve allows the circulation of fluid from the CT tool string to the well under normal operating conditions. By dropping a ball, this circulation path is closed off and fluid is diverted through the tool string. This valve is useful when a deliberate applied pressure needs to be delivered to the CT work string.

Downhole Filter

The DTI CT Downhole Filter removes particles from circulating or produced, fluid to prevent them passing through Motors or other downhole tools that are sensitive to debris.

CT Surface Filter

The DTI CT Surface Filter is used to remove particles from circulating fluid, thus protecting downhole motors and other downhole tools that are sensitive to debris.

Pump Out Choke Probe

The DTI CT Pump Out Choke Probe is run below the Hydraulic Knuckle Joint in the Multi-Lateral Entry System. The Pump Out Choke Probe is generally sized so that the Hydraulic Knuckle Joint is prevented from fully articulating inside the main wellbore casing. Once the lateral wellbore is located the Pump Out Choke Probe moves into the casing window allowing the Hydraulic Knuckle Joint to fully articulate. This opens the bleed ports and provides a pressure signal that the lateral wellbore has been located.

Flow Control Valve

DTI's Flow Control Valve allows the circulation of fluid from the CT tool string to the well under normal operating conditions. By increasing CT flow rate, at a predetermined tool string pressure, the flow path will be fully diverted through the tool string.

Active Pressure Relief Valve

Use the DTI Active Pressure Relief Valve to prevent BHA over-pressure and protect tools.

Cement Valve

The DTI Cement Valve will support a column of fluid in the CT until an increase in pressure is applied to the column of fluid. When the pressure inside the CT exceeds the well hydrostatic pressure by a pre-determined amount the Cement Valve will open.

Hydrostatic Valve

The DTI CT Hydrostatic Valve supports a column of fluid in the CT until an increased pressure is applied. By reducing CT pressure, the valve will close and the fluid will cease to flow through the valve.

Back Pressure Valve

The DTI Back Pressure Valve will support a column of fluid in the CT. When the pressure inside the CT exceeds the well hydrostatic pressure by a pre-determined amount the Back Pressure Valve will open and fluid can be circulated through the BHA.

Bleed Sub

The DTI CT Bleed Sub enables any residual pressure within the coiled tubing bottom hole assembly to be vented to atmosphere in a controlled manner.

Velocity Check Circulation Valve

The VCCV allows the combined circulation of CT fluid through the valve and via the side ports until a pre-determined flow rate has been reached. The valve will then shut off the through-flow and only circulate out of the side ports.

Dart and Ball Catcher

The Dart and Ball Catcher is designed to contain fluid and indicate when the coiled tubing reel has been successfully circulated and drifted.

CT Torque Through Knuckle Joint

Our Coiled Tubing Torque Through Knuckle Joint is a fully sealed joint that provides the CT tool string with an inclusive 15 degrees of flexible deviation. The I.D. at the knuckle is beveled in order to maximise the bore when the joint is at full deviation. The knuckle will also transmit torque.

Coiled Tubing Non-Rotating Fluted Centraliser

DTI's Coiled Tubing Non-Rotating Fluted Centraliser is a full bore component that ensures that the CT tool string is fully centralised within the well tubing. The O.D. is usually specially sized to tubing drift or to pass through nipple restrictions. Large fluted flow paths are incorporated into the O.D. to maximise fluid by pass and shoulders are fully beveled to prevent tool string hang up.

Flow Through Bow Spring Centraliser

The DTI CT Bow Spring Centraliser provides centralisation to CT tool string, whilst retaining the ability to pass through smaller tubing restrictions. The bow springs can either be incorporated as a conventional tool or slipped over the tool string on carriers and locked in place with set screws. The bow springs are replaceable and easily changed out without the need to remove any tool from the tool string.

Venturi Junk Basket

The DTI Venturi Junk Basket is used to collect downhole debris and retain it in the tool. Circulating flow creates a suction effect within the tool which draws debris up inside the junk basket. Inside the tool a metal filter screen, magnets and a flapper junk shoe retain debris in place so it can be removed from the well.

Hammerhead Bi-Directional Impact Hammer

The Hammerhead Bi-Directional Impact Hammer delivers a controllable high frequency up or down impact to a downhole device

Solutions across the energy spectrum

Transferring well technology from oil and gas to CCUS, hydrogen and geothermal, in support of the energy transition.